Tam Valley Depot

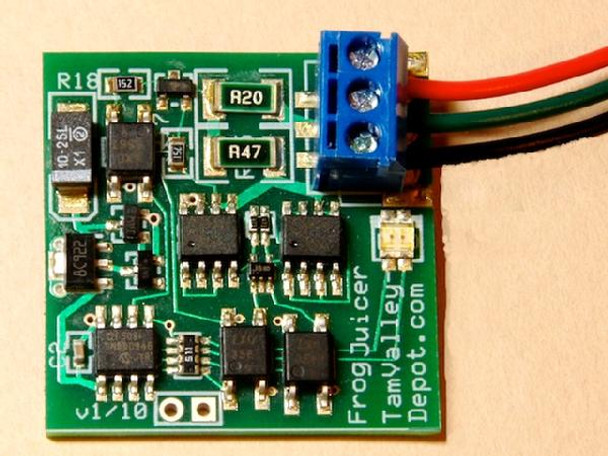

Tam Valley Depot DCC Mono Frog Juicer (Polarity Reverser for Frogs)

- MPN:

- MFJ003U

- Condition:

- New

Description

Tam Valley Depot DCC Mono Frog Juicer (Polarity Reverser for Frogs)

For all DCC systems including NCE PowerCab.

This board is an automatic polarity reverser for a single frog. Setup is simple, connect two wires to the DCC bus and one wire to a frog. The frog should be fully isolated. When a train crosses the turnout and the frog is the wrong polarity, the frog juicer will reverse the polarity so quickly that the train and the rest of the DCC system will never notice. Should not be used with boosters over 5 Amps. See the Dual Frog Juicer for 10 Amp boosters.

Please note - Frog Juicers are DCC (Digital Command Control) devices ONLY. They will not work with DC or 3-rail. They will work with most all DCC systems, Lenz, Roco, NCE (including the PowerCab), Digitrax, Zymo, MRC, CVP. If you don't see your DCC system here, don't worry, there are just too many to list them all!

Alas, they will not work with the Bachmann EZ-DCC system or the SPROG II as they do not have enough power to reach the 1.7 Amp switching threshold. However, if you use one or our boosters then you can use frog juicers and other auto-reversers with these systems.

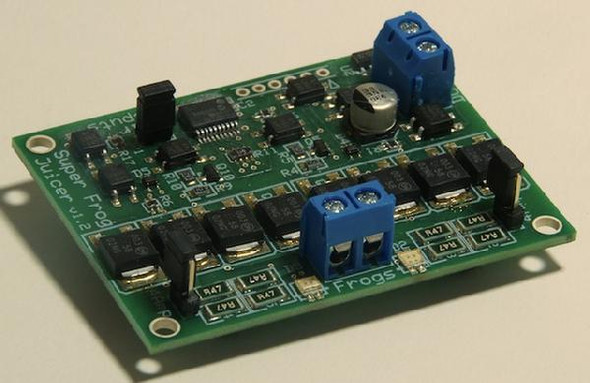

Peco Electrofrog Update- Hex Frog juicers have been modified to work with Peco electrofrog turnouts (and other power-routing turnouts) as they come. The mono-frog and the dual-frog juicers can be used with a couple of electrofrogs (like on a module) but not if you have more than 4 electrofrogs. You still need to insulate the Peco electrofrog turnouts as in the instructions that come with the turnout. Peco Insulfrogs do not need a frog juicer as the frog is plastic and cannot be powered.

What are the pros and cons of a frog juicer vs a relay or switch?

The other way to switch the power is by using a switch or relay connected to the turnout movement or the control panel. Often a micro-switch is used that is tripped by the movement.

These can be difficult to adjust and keep adjusted. Another methos is to use a switch buil-in to the switch motor (i.e tortoise, blue-point, bullfrog or cobalt). These work well. They occasionally wear out and in this case you could add a frog juicer if you don't want to replace the switch motor.

Another strategy is to use a DPDT toggle to throw your turnout motors. In this case one set of the contacts on the toggle are used for the turnout motor and the other is used to power the frog. Toggle switches wear out over time but are usually relatively easy to replace. On layouts I operate on regularly that use this method we need to replace a toggle every few operating sessions. Relay can often be used in place of toggles. They can be connected to the logic that throws the turnout. Some complex situations such as 3-way turnouts or double crossovers that may require ganged relays to implement the logic needed for the proper powering of frogs based on point position. In this case a frog juicer is far simpler to implement. The main advantage of the frog juicer is simplicity - just connect a single wire to the frog and power the juicer from the DCC bus and you are done. Frog juicers are electronic and not subject to mechanical wear. Finally, there are situations where a frog is not connected to moving points, like a crossing, and there is no mechanical or electrical way to easily switch the frog power. In this case the frog juicer is ideal. Some turnouts, such as Peco electrofrogs, use power-routing. This is where the points touching the stock rails is sued to power the points and the frog as a unit. this works really nicely for about a year and then no amount of cleaning seems to be able to restore good contact. We have used hex frog juicers to restore these turnouts and make them operate better then new. Just connect a wire from the point/frog assembly to the frog juicer output. Using hex frog juicers with power-routing turnouts can also save you from modifying them to "DCC-friendly". This is because the hex frog juicer will handle the shorts that can occasionally occur by a wheel brifging the gap between the open point and the stock rail. Hex frog juicers have a special startup sequence that sequences each turnout on one at a time and checks for a short and thus starts each turnout in the correct polarity. The mono and dual cannot do this an dthis limits the number of electrofrogs you can connect to a command station through the frog juicers. Otherwise you can get a situation where too many turnouts are in the wrong polarity for the booster to start the layout without immediately shutting down. If this confuses you - all you have to remember is to use the Hex frog Juicer with electrofrogs. Frogs need to be powered to prevent interruptions in poer to your locomotives as they pass over a turnout. Some turnouts have very short frogs or plastic frogs and this can be ignored. Some modelers only run 8-wheel and 12-wheel diesels and don't need to power their frogs as they always have good contact. However short diesels and steam locomotives often balk at unpowered frogs. It is embarrasing to have to get out the 0-5-0 to rescue a stalled locomotive. The issue with powering a frog is that you have to switch the power to the same polarity as the points when the turnout is thrown. The frog juicer automatically switches the power on a frog. A wire from the frog juicer is used to power the frog - if the frog is of the wrong polarity adn shorts, the frog juicer detects the current surge and nearly instantaneously switches the power before the locomotive decoder or the command station can notice.

|

Additional Resources

MANUFACTURERS WEBSITE: |

|

SOUND CONFIGURATION & SOUND FILE RESOURCES: |

|

FIRMWARE & SOFTWARE RESOURCES: |

|

PRODUCT MANUALS & TECHNICAL DOCUMENT RESOURCES: |

|

MANUFACTURERS WARRANTY & REPAIRS: |

|

ADDITIONAL INFORMATION - DCC TIPS: |

|

ADDITIONAL INFORMATION (1): |

|

ADDITIONAL INFORMATION (2): |

Additional Information

PRODUCT CLASS : |

All Scales |

DECODER TYPE: |

Accessory - Frog Polarity |

DECODER INTERFACE (PRIMARY): |

Screw Terminal |

DECODER INTERFACE (SECONDARY): |

NA |

SIZE-INCH (L x W x H): |

0 x 0 x 0 in |

SIZE-METRIC (L x W x H): |

0 x 0 x 0 mm |

FUNCTION CURRENT: |

5A each |

TRACK SECTION INPUT-OUTPUT: |

1 |

CIRCUIT BREAKER: |

NO |

AUTO REVERSER: |

YES |

OCCUPANCY DETECTION: |

NO |

FUNCTION CONTROL INPUTS: |

0 |

SWITCH MOTOR FUNCTION OUTPUTS: |

0 |

STATIONARY - SIGNAL LIGHTING FUNCTION OUTPUTS: |

0 |

SWITCH MOTOR TYPE - STALL MOTOR (TORTOISE SLOW-MOTION): |

NA |

SWITCH MOTOR TYPE - TWIN COIL SOLENOID (ATLAS SNAP): |

NA |

SWITCH MOTOR TYPE - BI-POLAR SOLENOID (KATO-PIKO-LGB): |

NA |

SWITCH MOTOR TYPE - SERVO MOTOR: |

NA |

PROTOCOL: |

NA |

BI-DIRECTIONAL COMMUNICATION: |

NA |

ADDITIONAL FEATURES: |

NA |

NOTES (1): |

NA |

NOTES (2): |

NA |