ZIMO DCC

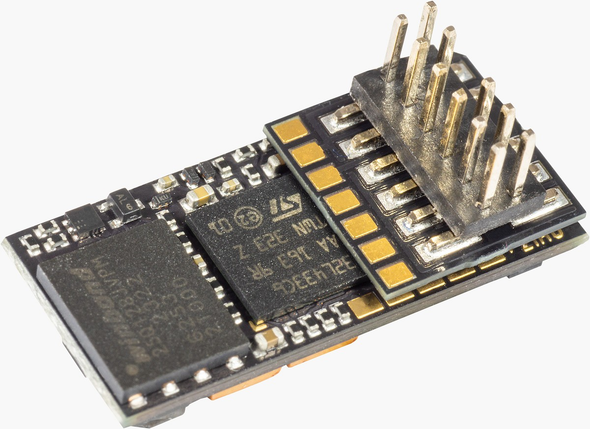

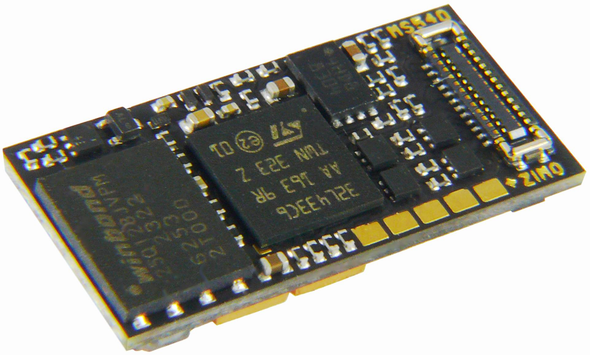

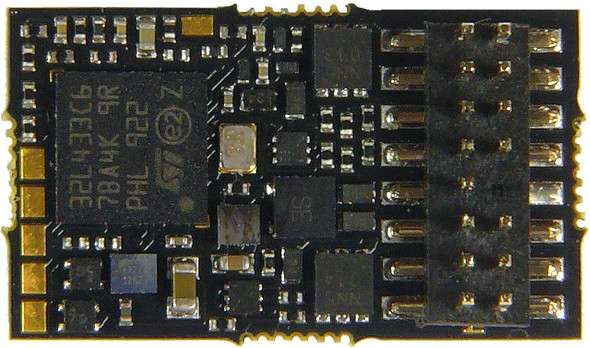

ZIMO MN140P12 Micro DCC Decoder - E24 Integral Connector to NEM658 PluX12 Integral Connector

- UPC:

- 9009606140128

- MPN:

- MN140P12

- Condition:

- New

Save More With Volume Discounts…

| Buy 5 - 9 | $63.57 each |

| Buy 10 or above | $61.63 each |

Description

ZIMO motion decoders also offer all of the world class functions of our sound decoders: silent drive selectable between 20 or 40 kHz, adjustable BEMF, special settings for coreless motors, optional kph or mph speed control, constant stopping distance, HLU, ABC, advanced uncoupling functions, smart stopping (prevents stops on dirty track sections), updatable firmware, and RailCom.

ZIMO MN Series non-sound decoders correspond technologically to MS sound decoders. The identical microcontrollers and largely the same components for the power electronics (motor output stages, etc.) are installed in both product classes, and of course also the software is (further) developed together to a large extent. These similarities result in, among other things, the same driving behavior, the same mapping, the same script capabilities and a similar project organization, whereby there are sound projects for sound decoders on the one hand and projects (without sound) for non-sound decoders on the other, which contain both configuration data (i.e. essentially CV lists) and GUI data.

ZIMO MN140 DCC Decoders offer the following features:

The MN140 is the "sub-micro E24 model" for N scale motion control in the ZIMO decoder range. It comes in a single format, has plenty of power, 4 function outputs, and 4 convertible logic level outputs.

This model has dedicated circuitry for external energy storage, especially important for silky smooth motion control.

- 0.7A Continuous Motor current - 1.5A Peak Power

- 4 - Normal Function Outputs

- 0.7A Total current with overload protection

- 4 - Logic Level Function Outputs

- 2 - 5.0V Low Voltage Outputs

- 0.2A Total current - Convertible to SUSI

- SUSI Compatible with connection

- Energy Storage Compatible with connection (15,000 mF max.)

Feature Summary:

- 14, 28, 128 speed steps

- 3-way adjustable back-EMF

- Selectable frequency for noiseless operation

- For all DC motors including coreless

- 3-point or 28-step speed table

- 5 digit addressing

- All US lighting effects with programmable timing and dimming

- Free mapping, NMRA mapping or Swiss mapping function control

- NMRA bidirectional communication (RailCom)

- Short circuit protection

- Thermal protection

- Reliable overload protection

- User updateable firmware

- Editable and updatable sound files

ZIMO Features and Characteristics:

- Conforms to applicable NMRA DCC Standards and Recommended Practices.

- Address range from 1 ... 10239, consist range 1 ... 127; Functions controlled by main or consist address.

- 14, 28 or 128 External Speed Steps, 256 or 1024 Internal Speed Step resolution for incredibly smooth motor control.

- 3-point adjustable speed curve (CVs #2, 5, 6) or fully programmable 28-step speed table (CV #67 - 94).

- Top speed (CV #5) can be used even when the speed table is used (CV #67 - 94), which means that all entered table values will be reduced automatically (i.e. to 80% if CV #5 holds a value of 200 instead of 252).

- Switching Mode button function - Selectively switches to low speed and/or reduces or even removes programmed momentum.

- Multiple CV sets, predefined or self-defined: by storing more than one CV set, a locomotive can quickly and easily be changed for various duties that require different CV settings (i.e. single locomotive or consist, layout at home or club etc.)

- Supports Operations Mode (Program On Main) and Service Mode (Program Track) CV Programming.

- Special programming mode called "Pseudo Programming" for Digitrax, Lokmouse-2 and other systems with only 2-digit display (up to 99).

- Hard reset with CV #8 = 8; Optional hard reset to Alternate CV Set or sound project with CV #8 = 0.

- Automatically recognizes and switches between the MOTOROLA and DCC protocols.

- Operates with standard DC analog power packs, PWM power packs, and DC power supply. Motor regulation and momentum are also available in analog operation.

- AC analog operation with Marklin transformers. ZIMO decoders recognize the power surge that initiates a direction change.

- User Updatable - Install the latest firmware yourself, in minutes, at no charge and without opening the locomotive. All ZIMO decoders come with this feature (including function and accessory decoders). The new firmware is always available at no charge from the ZIMO or ZIMODCC web site. (Requires MX10, MXULFA, or other device)

ZIMO Safety Features:

- Reliable high voltage protection and short circuit protection for motor and function outputs.

- Thermal protection (100 - 120 C), shuts decoder down and notifies user with flashing headlights.

- Models available for use with track voltage up to 35 V (MX644, MX699).

ZIMO Motor Control Features:

- ZIMO Silent Drive motor control with Self-Optimization and numerous settings for manual optimization:

- PID parameters

- Reduce or cut regulation

- Reduce or cut regulation above defined speed

- Modify EMF sampling rate.

- Realistic momentum:

- Standard momentum (CV #3 and 4)

- ZIMO exponential (nonlinear) momentum for extremely prototypical acceleration and deceleration

- ZIMO adaptive acceleration to prevent startup jolt

- High frequency Silent Drive motor control, selectable between 20 or 40 kHz, suitable for use with:

- Standard DC motors

- Coreless motors (Faulhaber, Maxxon...)

- Difficult cases, such as the round Fleischmann motor

- Old motors requiring low frequency 30 - 150 Hz

- C-Sinus and SoftDrive motors as found in Marklin/Trix locos

- The Self-Optimization feature of the decoder automatically tunes the motor control parameters of the decoder to the locomotive.

- Designed to startup at extremely low threshold voltage.

- Adjustable compensation for gear backlash during direction changes to eliminate startup jolt.

- Mph or km/h speed control. Each speed step (1 - 128) is interpreted as 0.5 mph, 1 mph or 2 mph (for high speed trains). All locomotives on the layout are adjusted by means of a semi-automatic calibration section (i.e. 160 scale-yards = 72.83 on the layout). In operation, the speed is kept as exact as possible by continuously recalculating and readjusting it.

- Special circuitry to prevent interference from capacitors, choke coils, which are often found on motors. In some cases removal of these components may still be beneficial (See Decoder Manual).

- Uninterrupted operation (no stalling, stopping and new startup) during continuity interruptions of up to 1 second. All current models of ZIMO decoders have Common (+) and Ground (-) pads available for adding external capacitors. Many ZIMO decoders have special circuitry for adding external capacitors (SPEIKOMP, SPEIGOMP) which minimizes programming interference.

- Uninterrupted operation on dead track sections. The decoder firmware prevents the loco from stopping when track power is lost, even while the loco is coming to a scheduled stop. This ensures that the loco can start up again even after the capacitors dissipated the stored electricity. Note: Requires external energy storage module MXSPEIK or MXSPEIG, other similar products or self-made modules connected to the decoder.

ZIMO Function and Function Output Features:

- 4-15 Normal function outputs and logic-level outputs, depending on decoder type.

- 2-4 Low voltage 5.0V servo outputs, depending on decoder type.

- SUSI interface for the connection of other external modules, most often sound modules.

- NMRA function mapping.

- ZIMO Free Function Mapping procedure (CV #61=98) enables mapping of any output to any function key, directional or non-directional, which is not possible with NMRA function mapping.

- ZIMO Swiss Function Mapping (CV #61=...) for special cases such as direction dependent taillights and cab light in Swiss engines.

- Numerous special effects:

- Soft start for function outputs

- Function output dimming

- Function dependent low/high beam

- Adjustable flasher

- Stop light logic

- Output time-out function

- Firebox Flicker

- Speed and load dependent smoke generation and fan control

- All US lighting effects

- Mars Light

- Rotary Beacon

- Strobe and Double Strobe

- Gyra Light

- Ditch Light - Type I and II

- Variable cycle times and minimum dim values.

- Special CVs for automatic uncoupling (aka The ZIMO Coupler Waltz). After pressing the function key defined for this action, the loco backs up a few millimeters to unload the couplers then actuates the uncoupler and moves forward away from the train. The distance the loco backs-up and moves forward as well as the loco speed step is definable with CVs.

Note: On some decoders, the same function outputs can be used as either logic-level, servo or SUSI outputs.

ZIMO Common Function Outputs (a.k.a. Logic Level Outputs):

The common function output, also called a "Logic Level" output or "unamplified" output, refers to the voltage level at the terminal (0V for "off", 5V for "on"). The funtion output has an internal protection resistor equal to 10K Ohms resulting in 0.5 mA maximum available output current.

The use of the common function outputs is determined with CV settings:

CV # 124:

- Bit 7 = 0 -> SUSI

- Bit 7 = 1 -> Logic Level

CV's # 181, 182

- If set, the common function outputs are used for servo control.

Logic Level Outputs of [C] and [D] Types:

In all decoders with 21-pin "MTC" interface (either a [C] - type or a [D] - type, e.g. MX634C MX634D or MX644C); the two variations differ in the execution of function outputs FA3 and FA4:

- "D" - Outputs FA3 and FA4 are "normal" amplified outputs

- "C" - Outputs FA3 and FA4 are "logic level" outputs

Note: Logic-level outputs can power one LED or any other load by using an external amplifier (i.e. M4000Z)."Logic Level" outputs can be amplified by adding the ZIMO M4000Z Logic Level Function Amplifier or similar devices.

CAUTION: "Logic Level" outputs are NOT active in the default configuration of the decoder because they use the same ports as the SUSI interface (clock and data) as well as the servo-control lines.

ZIMO Train Control and Feedback Features:

- DC braking distance, ABC (stopping on asymmetrical DCC signal), Marklin braking section,

- ZIMO "signal dependent train control" (HLU) with speed limits in 5 steps and "stop before red signal",

- ZIMO loco number recognition only with ZIMO DCC system and ZIMO track section modules,

- Constant braking with two variations:

- Always start braking immediately

- When speed is low, stop in same place

- RailCom - bidirectional communication hardware is found in all ZIMO decoders:

- km/h feedback

- CV "on-the-main" read-out and confirmed programming

- RailCom address feedback

- Many more RailCom applications in future software releases

RailCom is a Trade Mark of Lenz GmbH

Additional Resources

MANUFACTURERS WEBSITE: |

|

SOUND CONFIGURATION & SOUND FILE RESOURCES: |

|

FIRMWARE & SOFTWARE RESOURCES: |

|

PRODUCT MANUALS & TECHNICAL DOCUMENT RESOURCES: |

|

MANUFACTURERS WARRANTY & REPAIRS: |

|

ADDITIONAL INFORMATION - DCC TIPS: |

|

ADDITIONAL INFORMATION (1): |

|

ADDITIONAL INFORMATION (2): |

Additional Information

PRODUCT CLASS : |

Micro (N-HO-S*) |

DECODER TYPE: |

Motor + Function |

DECODER INTERFACE (PRIMARY): |

NEM658 - PluX 12/16/22 |

DECODER INTERFACE (SECONDARY): |

ESU E24 |

SIZE-INCH (L x W x H): |

0.53 x 0.34 x 0.09 in |

SIZE-METRIC (L x W x H): |

13.5 x 8.7 x 2.3 mm |

MOTOR CURRENT (CONTINUOUS): |

0.7A |

MOTOR CURRENT (PEAK): |

1.5A |

FUNCTION CURRENT (MAX): |

0.5A total |

NORMAL OUTPUT FUNCTIONS: |

4 |

LOGIC-LEVEL FUNCTIONS: |

4* |

SERVO OUTPUT FUNCTIONS: |

2* |

FUNCTION INPUTS: |

2* |

KEEP-ALIVE INTERFACE: |

Hardwire - Solder Pad** |

KA INPUT VOLTAGE (MAX): |

NA |

KA TOTAL CAPACITANCE: |

NA |

CV PROGRAMMING: |

Service Mode + P.O.M. |

FIRMWARE UPDATE: |

Yes - MXULFA required |

PROTOCOL: |

NMRA DCC, M4, Motorola |

BI-DIRECTIONAL COMMUNICATION: |

RailCom |

ADDITIONAL FEATURES: |

NA |

NOTES (1): |

* - Optional configuration - see manual |

NOTES (2): |

** - Optional on interface connector |