About DCC Decoders

Last Updated 250309 - Page Under Construction

This page is published to help Streamlined Backshop customers use the information provided on the site to filter through the hundreds of models of DCC decoder available to find the best solution for their project.

It is also offered as a general primer on DCC decoders. Understanding how a decoder works and the options available will help you make better choices in the beginning and better installations in the end.

When I launched the new store in November 2023, we stocked...

- 36 models of Function Decoders

- 238 models of Motor Decoders

- 226 models of Sound Decoders

- 45 models of Stay-Alive Devices

- 105 models of of Adapter Boards

- 228 models of Speakers

- 70 models of Accessory Decoders

Those are some big numbers that continue to grow!

From the outset, I designed the STREAMLINED BACKSHOP website to simplify the DCC decoder shopping experience, to be a resource for DCC users, and to be a platform to share our knowledge and expertise about all things DCC with the model railroading community.

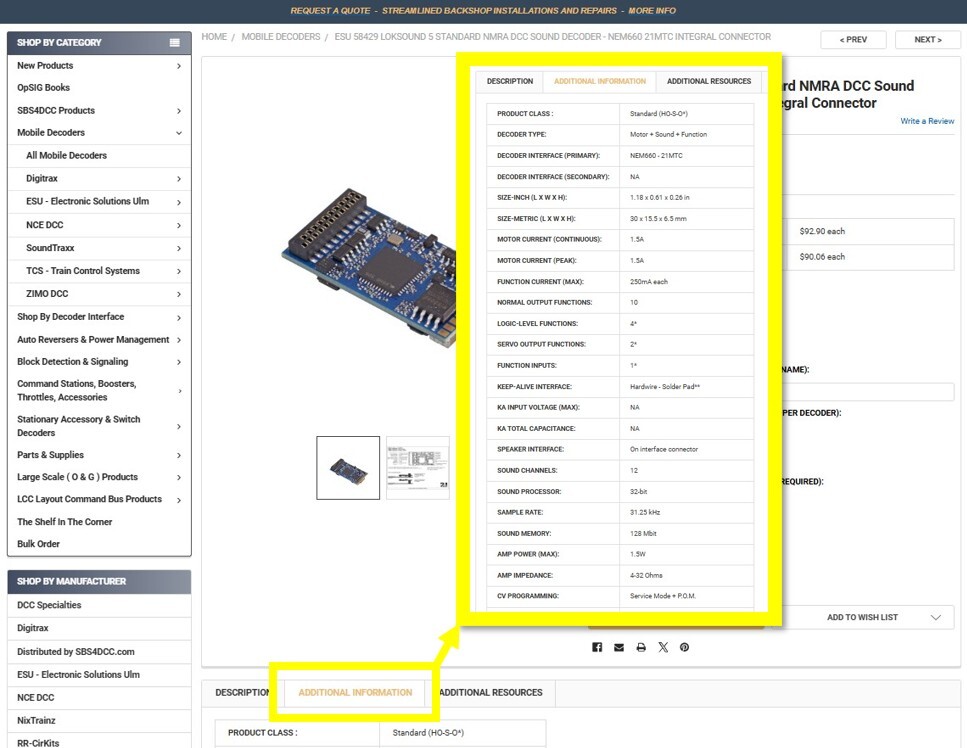

A table on the ADDITIONAL INFORMATION tab on the PRODUCT INFORMATION page of every DCC decoder is populated with the features and technical specifications of the product in a highly standardized format.

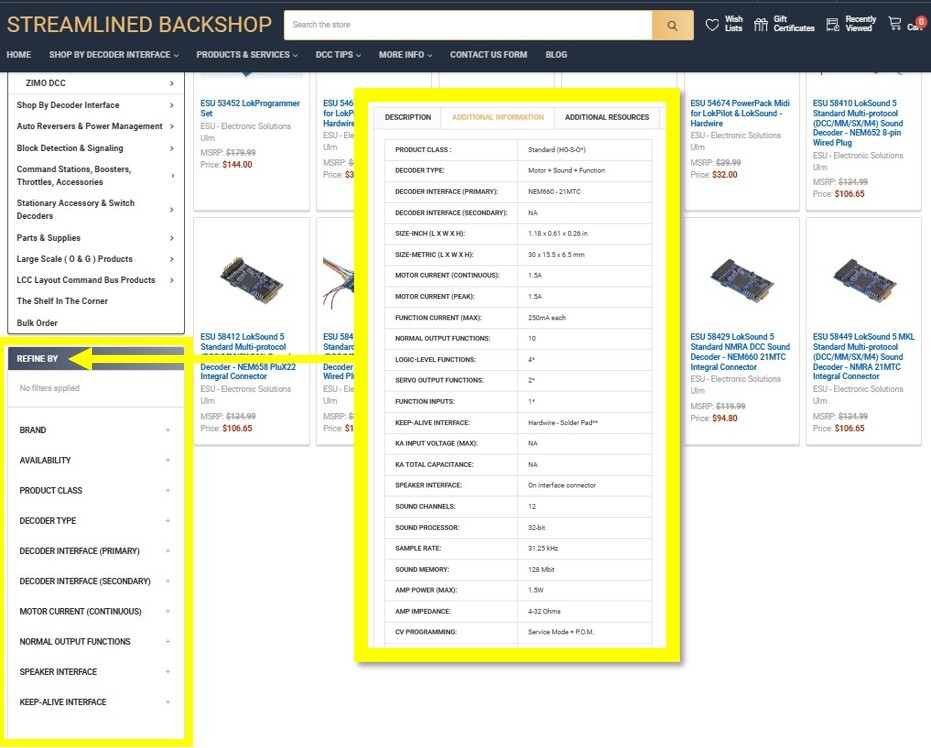

That standardized data has also been used to employ a powerful filter available in the category views to help search for and narrow down the best decoder for your project.

This page uses the same standardized data to help explain everything you need to know ABOUT DCC DECODERS...

Two additional details to know about using the SBS4DCC website.

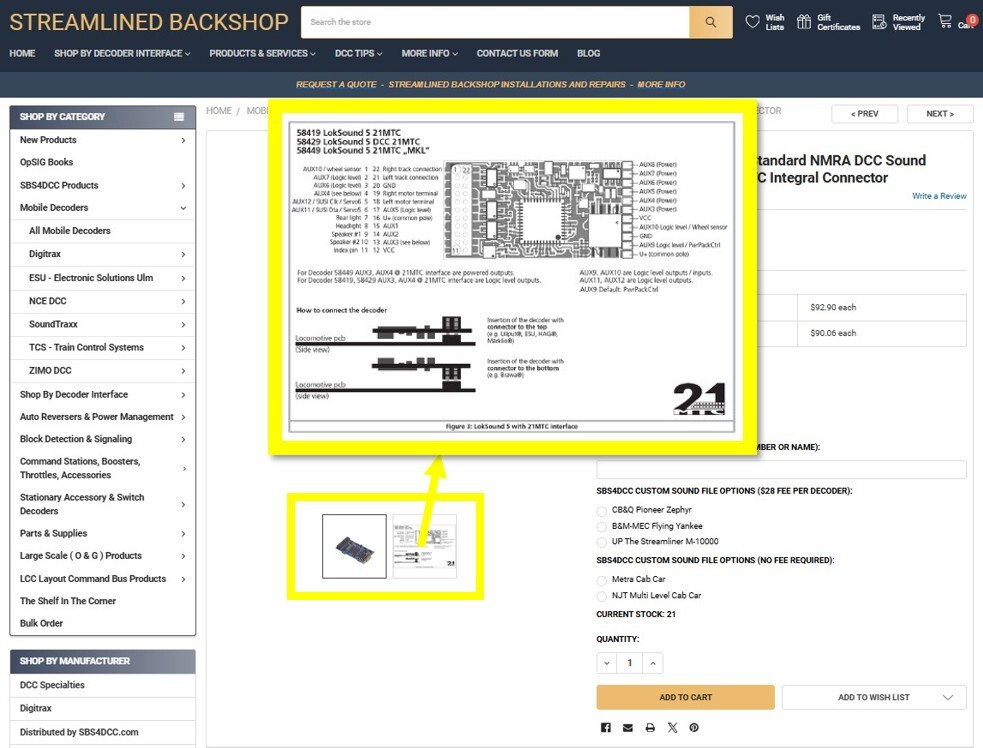

First, I have included a copy of the pin out diagram of each decoder in the IMAGES CAROUSEL on the PRODUCT INFORMATION page. This simple image tells you so much about the product and how to use it.

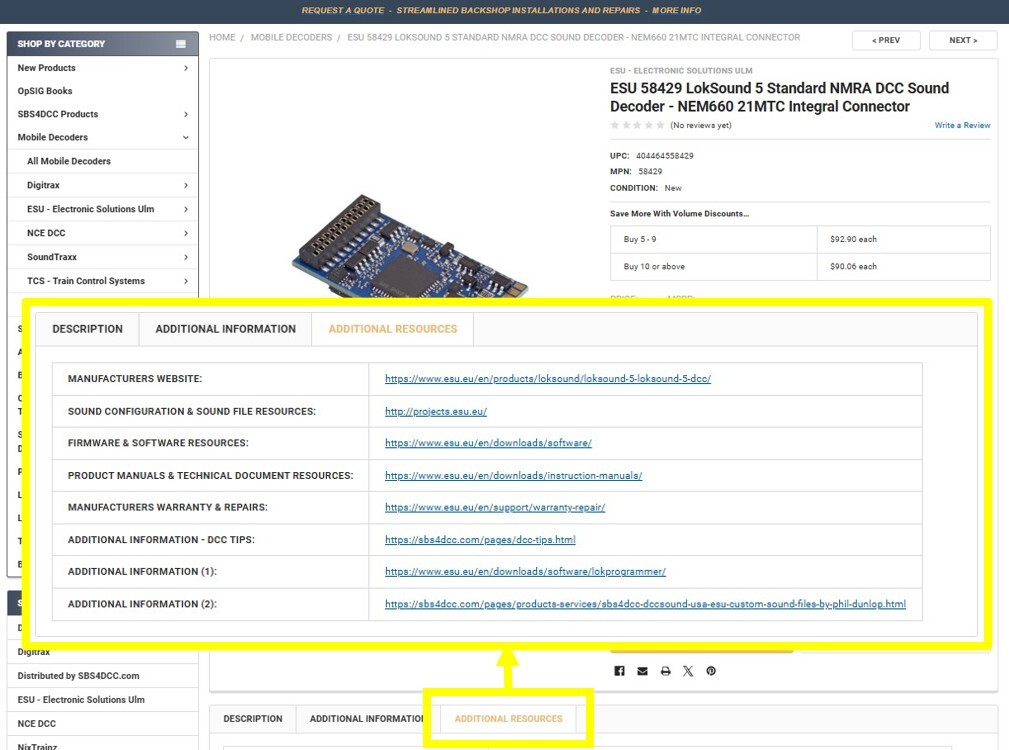

Second, a table on the ADDITIONAL RESOURCES tab on the PRODUCT INFORMATION page of every DCC decoder is populated with live links to important information and additional resources about the product in a highly standardized format including the manufactures site, manuals, software and sound file databases, and anything else that I would use to research and interrogate the product.

Don't overlook these valuable, handy, time-saving resources.

ABOUT DCC DECODERS

A DCC Decoder is an energized electrical device that receives instructions from a DCC Command Station and Throttle to control a model railroad locomotive.

There are two basic families of DCC Decoders, Mobile Decoders and Stationary Decoders. Mobile Decoders are generally designed to be installed in rolling stock to control head lights, motor and to add sound to simulate prime movers and operating equipment. Stationary Decoders are designed to be permanently mounted to the layout to control stationary components like building lights, sound modules, and switch machines. This discussion is focused on the Mobile Decoder but the basic concepts apply to Stationary Decoders.

There are a couple of basic tenets of DCC the must be explicated to understand the function and purpose of a DCC decoder. This is the crux of the argument for using DC or DCC power to control a model train or layout. This discussion assumes we have a simple oval of track with only the essential components needed to operate the locomotive. There are hundreds of exceptions and caveats and add-ons and workarounds that could be introduced to complicate this simple explanation... let's keep it simple.

A DC Transformer supplies variable voltage to the rail which is collected, or picked up, by a model railroad locomotive to energize a motor. The speed the motor turns is relative to the voltage supplied to the rail. The polarity of the voltage supplied to the rail pair determines the rotation the motor spins and therefore the direction the locomotive travels. The polarity can be reversed by means of a slide switch on the DC Transformer. If there are multiple locomotives on the on the same track, all locomotives will move in the same direction and at the same speed. They change direction in unison when the polarity is reversed. Other electrical components in the model like incandescent bulbs and LEDs for headlights are also energized by the same variable current so the are really dim when the train moves slowly and really bright when it moves fast.

A DCC Command Station supplies fixed voltage to the rail and transmits a command signal which is collected, or picked up, to energize and provide operating instructions to a DCC Decoder installed in a locomotive or piece rolling stock or on the physical layout. The output of the command station is alternating polarity DC, referred to as square wave DC because it functions like AC power, and the command signal that is embedded in power wave form.

The first stage of the decoder circuit is a VOLTAGE RECTIFIER. The most basic function of a DCC Decoder is to rectify the alternating, square wave DC voltage from the Command Station to traditional fixed polarity DC voltage to energize the circuit. This output voltage from the diode bridge of a DCC Decoder is more or less identical to the output of a DC Transformer. It's just fixed DC voltage. It can be used to do everything we have always done in model railroading like energize a motor or LED. The embedded command signal however, allows us to communicate with and control a microprocessor on the DCC Decoder to control that fixed DC voltage in ways our fathers and grandfathers only dreamed of. That's it... that's the magic of DCC.

The second stage of the decoder circuit is MOTOR CONTROL. The microprocessor on the DCC Decoder "decodes" the command signal to control an H-bridge circuit that energizes the motor by means of diagonally-opposed switches, control the speed of rotation by means of a pulse width modulated signal (PWM), and control the direction of rotation by switching the polarity of the PWM signal.

A parallel second stage of the decoder circuit is FUNCTION CONTROL. The microprocessor also controls transistors that act as on/off switches, also called the function outputs, to control other electrical components in the model like incandescent bulbs and LEDs for headlights. The headlights never change in intensity because the voltage is supplied at a fixed value.

A DC Transformer supplies variable voltage and has universal control of all locomotives on the same track.

A DCC Command Station and Throttle (DCC System) supplies fixed voltage to a DCC Decoder that supplies variable voltage to and has discrete control of the locomotive it is installed in, regardless of how many locomotives are on the same track.

DC Transformers drive the track, DCC Systems drive the decoder and therefore the locomotive.

A third stage of the decoder circuit is SOUND GENERATION. The addition of the microprocessor to the control circuit of a model railroad locomotive enables the addition of logic and control of an audio output circuit, an amplifier and speaker, to generate sound. The microprocessor is programmed to play highly edited .wav files in conjunction with the various logic events or "commands" received from the DCC System.

ADD BLOCK DIAGRAM GRAPHIC

It is important to note that a sound decoder can be energized using a DC transformer but the circuit requires a minimum voltage value to function. The quality and functionality of the sound output is greatly affected by the variable output of a DC Transformer. Conversely, the fixed voltage output of a DCC System is optimal for controlling the sound output and another advantage of DCC compared to DC.

This same discussion also applies to the functionality of a fairly recent development in model railroad locomotive control, the Stay-Alive circuit. The Stay-Alive circuit or device is basically a collection of capacitors that act like a battery backup to supply smooth, continuous power to the DCC Decoder when imperfections like dirty track and wheels, poor trackwork, and such interrupt or break the continuity of the "pick-up" circuit. Those interruptions or breaks cause the motor to jerk or stall out and are the worst nuisance of model railroading. The fixed voltage of the DCC System enables the Stay-Alive Device to work.

Therefore, based on this discussion, there are three basic subfamilies or types of Mobile DCC Decoders; Motor + Function, Function only, and Motor + Function + Sound. All DCC decoders in a subfamily are more or less the same and their capability is determined by which stages are included in the circuit design.

PRO TIP... all decoders have the same basic color coded connections, the only thing that really changes are the features and the size...

- RED + BLACK - Right + Left Track Power Input

- ORANGE + GREY - Right + Left Motor Power Output

- BLUE - Function Common - This is the positive output of the RECTIFIED VOLTAGE CIRCUIT. On most systems having a normal operating voltage of ~14V, Function Common supplies about 12V rectified DC to the FUNCTION CONTROL CIRCUIT after voltage drop through the circuit.

- YELLOW and WHITE - F0F/F0R Function Outputs - This is the negative, switched side of the FUNCTION CONTROL CIRCUIT. Each additional Function Output on a DCC Decoder will have a unique color coded connection.

- PURPLE or BROWN - Right + Left Speaker Output (Sound Decoders only)

I highlight this fact make the point that every decoder installation is more or less the same. It's the same seven (nine?) wires; only the shape of the plastic box you put it in changes. Making it all fit without a short circuit is the real challenge...

Let's explicate the filter data on the ADDITIONAL INFORMATION tab to understand the options and features of DCC Decoders better.

But first let me answer your question... "Why not just create a table of decoders X for model Y?"

Take for example the N scale Kato F7. I am aware of at least three distinct versions of this model each requiring a completely different decoder and installation technique. Now imagine all of the different Kato models and all of the different model manufacturers and all of the different decoder manufacturers, and all of the different decoder models each manufacturer offers... exponential possibilities... I could never keep up...

So now you are probably asking the question... "How on earth can I figure this out?"

There is no magic bullet or easy button here. The fact is there really is no perfect solution, only the solution that works best for you. If you only use brand X, great... here are the options. If you prefer hardwire vs drop-in, great... here are the options.

This is MY best solution. This is how I figure it all out. This is how I choose a decoder.

BRAND and AVAILABILITY

Streamlined Backshop will only carry products from reputable DCC suppliers and manufactures. The BRANDS we represent have demonstrated their ability to supply quality products and provide a reasonable level of technical support.

You can read more about PRODUCT AVAILABILITY on the STORE INFO page.

Remember there are live links on the ADDITIONAL RESOURCES tab to important information and additional resources about the product in a highly standardized format including the manufactures site, manuals, software and sound file databases, and anything else that I thought would be useful to research and interrogate the product.

PRODUCT CLASS

I created the PRODUCT CLASS filter to provide a way to reduce the collection of possibilities to the options that are most relative to your needs. Z scale modelers don't have much use for G scale sized decoders and vice versa. These are SUGGESTIONS ONLY and really don't mean much beyond a way to group related items based on their physical size, typical application and use.

Options include...

- All Scales

- HO Scale - Board Replacement

- Large Scale (S*-O-G)

- Micro (N-HO-S*)

- Nano (Z-N-HO*)

- N Scale - Board Replacement

- Proprietary*

- Standard (HO-S-O*)

- Z Scale - Board Replacement

Note that the * when used to reference a model scale indicates a product may be suitable for use in some applications in noted scale. In all cases, more research and evaluation is required to determine if the product is suitable for YOUR application.

There is no such thing as a N scale decoder, except maybe for the proprietary board replacement designs that generally only fit the intended model. Any decoder can be used in any model so long as it is suitable for the application.

The most important criteria to use when selecting a decoder are...

- Decoder Type

- Decoder Interface

- Physical Size

- Motor Current Rating

The other features and specifications matter but these four specifications determine if the product is suitable for a specific model or application.

DECODER TYPE

I created the filter DECODER TYPE filter to provide an additional way to reduce the collection of possibilities to the options that are most relative to your needs. The types are relative to the subfamilies described in the ABOUT DCC DECODERS section above.

Options include...

- Function Only

- Motor + Function

- Motor + Function + Adapter Board

- Motor + Function + Adapter Board + Keep Alive Device

- Motor + Function + Keep Alive Device

- Motor + Sound

- Motor + Sound + Function

- Motor + Sound + Function + Adapter Board

- Motor + Sound + Function + Adapter Board + Keep Alive Device

- Motor + Sound + Function + Keep Alive Device

- Motor Only

- Sound + Function

- Sound Only

Additional options include...

-

Accessory - Layout Lighting

-

Accessory - Signal*

- Adapter Board

- Adapter Board + Keep-Alive Device

- Keep-Alive Capacitor

- Keep-Alive Device

- Smoke Generator Control Board

-

Wire Harness

These subfamilies simply create additional logical groupings of products related DCC Decoders.

A new subfamily of products introduced here is the ADAPTER BOARD, sometimes referred to as a motherboard. A DCC decoder is added to, or plugged into, the ADAPTER BOARD to make it functional with DCC. This group of products can serve three purposes depending on the product...

- Convert the interface of a decoder to match the existing interface in the electrical circuit of the locomotive

- Serve as the permanent component in the electrical circuit of the locomotive so the actual decoder can be installed and removed easily

- Add additional features and functionality to the electrical circuit of locomotive

- Can be used to repair or replace the original MOTHERBOARD supplied with a DCC Decoder or model locomotive

In all cases, an adapter board is dumb device that must have a decoder added to complete the circuit. In all cases, the actual decoder is a separate component and not a permanent part of the ADAPTER BOARD.

Another new subfamily of products introduced here is the WIRE HARNESS. They are similar to the ADAPTER BOARD except that they are generally made of loose wires instead of a rigid circuit board. This group of products can serve three purposes depending on the product...

- Convert the interface of a decoder to match the existing interface in the electrical circuit of the locomotive

- Serve as the permanent component in the electrical circuit of the locomotive so the actual decoder can be installed and removed easily

- Add a separable junction to the circuit to make it easy to separate the shell of a diesel from the chassis or separate the tender of a steam locomotive from the engine

- Can be used to repair or replace the original WIRE HARNESS supplied with a DCC Decoder

Note that the * when used to reference a DECODER TYPE indicates a unique feature or capability. Additional research and evaluation is required to determine if the product is suitable for YOUR application.

DECODER INTERFACE

All DCC Decoders have a standardized DECODER INTERFACE thanks to the NMRA, MOROP and RailCommunity organizations that work hard to insure that same exponential list of BRAND-LOCOMOTIVE-DECODER-INTERFACE possibilities all work well together.

Options include...

- Drop-In - Prewired*

- Drop-In - Solder Pads

- Drop-In - Solder Pads*

- Drop-In - Solder Pads**

- ESU E24

- Hardwire - Pin Connector

- Hardwire - Single Wires

- Hardwire - Single Wires*

- Hardwire - Single Wires + Solder Pads

- Hardwire - Solder Pads

- Large Scale - Pin Header

- Large Scale - Screw Terminal

- Large Scale - Solder Pad

- NEM651 - NMRA 6-pin

- NEM652 - NMRA 8-pin

- NEM658 - PluX 12/16/22

- NEM660 - 21MTC

- NEM662 - Next18

- NMRA - Marklin 21MTC

- NMRA JST-Type

- NMRA Micro JST-Type

- Proprietary*

A DCC Decoder can have one or two interfaces...

- DECODER INTERFACE (PRIMARY)

- DECODER INTERFACE (SECONDARY)

The DECODER INTERFACE (PRIMARY) is always the connection that interfaces with the model locomotive. The DECODER INTERFACE (SECONDARY) is an intermediate junction between the actual DCC Decoder and PRIMARY INTERFACE.

PRO TIP... This is important to explicate because you may need a specific decoder for a project because of DECODER TYPE but it is not available with the correct interface. If you know the decoder has a SECONDARY INTERFACE, you have the option to change the WIRE HARNESS or ADAPTER BOARD to make the product work.

PRO TIP...This is also important to understand when troubleshooting a decoder problem. You can have continuity through the circuit at the PRIMARY INTERFACE but have a bridged (shorted) or open circuit at the SECONDARY INTERFACE that is causing issues with the installation.

Be sure to check out the SHOP BY DECODER INTERFACE page that provides information about the standards and technical data that define each type.

Be sure to also check out the SHOP BY DECODER INTERFACE category in the store where every model DCC decoder is sorted by decoder interface to help narrow choices quickly.

DECODER SIZE

DECODER SIZE is pretty straight forward and is usually present in both INCH and METRIC to save you the labor of conversion. The dimensions a specified by the manufacturer on their product page and only copied here.

SIZE-INCH (L x W x H): 1.18 x 0.61 x 0.26 in

SIZE-METRIC (L x W x H): 30 x 15.5 x 6.5 mm

As a general rule, the stated size is the overall dimension of the circuit board, components, and shrink wrapping. The DECODER INTERFACE connector may or may not be included in the measurements. Wires and such that extend beyond the main body of the decoder are generally not included in the measurement unless they affect the dimensions substantially.

Note that the * when used to reference a DECODER SIZE indicates the measurements stated are based on my own analysis and may vary from the manufacturers published data.

PRO TIP... use a piece of poster tack (or type of putty) to determine the available space inside a model.

- Disassemble the model

- Place a generous ball of putty in the working area

- Reassemble the model to compress the putty and mold it to the space

- Disassemble the model again

- Carefully remove and measure the putty to size the blind space

PRO TIP... make a small cardboard or 3D printed example of the decoder to determine if the decoder will fit in the model.

So it is written here, the actual conversion ratio is 1 INCH = 25.4 MM.

MOTOR CURRENT RATING

The MOTOR CURRENT RATING is, in my opinion, the single most important specification to consider when selecting a decoder. As I stated before, there is no such thing as a HO or N scale decoder; the question to always ask is, is the MOTOR CURRENT RATING high enough to meet the current draw of the motor in the project your are currently working on. I mean this exactly as stated; "the motor in the project you are currently working on".

Note that this is the rating of the MOTOR CONTROL CIRCUIT only and not the rating of the FUNTION CONTROL CIRCUIT or SOUND GENERATION CIRCUIT. Each stage or circuit of the decoder must be evaluated independently to understand if it is suitable for the application.

Specifications for motor current rating typically include...

- MOTOR CURRENT (CONTINUOUS)

- MOTOR CURRENT (PEAK)

MOTOR CURRENT (CONTINUOUS) is the amperage a motor can draw continuously in normal operation. It's important to note that a motor spinning at Speed Step 1 will draw significantly less amps than a motor spinning at Speed Step 28.

MOTOR CURRENT (PEAK) is locked-rotor current or stall current or the motor. It is the absolute maximum amperage the motor can draw before the electrical components the make up the MOTOR CONTROL CIRCUIT could be damaged.

PRO TIP... The easiest way to fatally damage a DCC Decoder is to exceed the MOTOR CURRENT RATING or failure to isolate the MOTOR CONTROL CIRCUIT from the input to the VOLTAGE RECTIFIER CIRCUIT. Stated more clearly, you can never have continuity between the RED + BLACK connections and the ORANGE + GREY connections. Never.

PRO TIP... Never assume the current draw is the same from project to project even if they are identical models purchased the same day. Electric motors are complex assemblies that will have variations in current draw. Never assume a motor is "good" just because it spins when you supply voltage to the circuit.

Be sure to check out the Measuring Motor Amp Draw and Stall Current page that provides additional information on the subject and instructions to perform the test.

DECODER FUNCTIONS

The phrase DECODER FUNCTIONS when discussing a DCC Decoder is broadly used to describe the collection of FUNCTION OUTPUTS that form the FUNCTION CONTROL CIRCUIT. Function Outputs are usually comprised of a transistor that acts as a switch to turn power on and off to a load, typically a LED. Decoder Functions are usually assigned to and controlled by FUNCTION KEYS on a DCC Throttle.

Specifications for decoder functions typically include...

- FUNCTION CURRENT (MAX)

FUNCTION CURRENT (MAX) is the maximum amperage that all combined loads can draw continuously in normal operation. As a general rule of thumb, you typically connect one load (LED) per function output. In the case of passenger car interior lights, you would connect one circuit of loads (multiple LEDs) per function output. Of course there are more caveats and exceptions to this; just be sure to understand the current each load or circuit of loads will draw.

In any case, when trying to determine how many functions you will need, the best way to answer this is to literally write down each load you plan to install in the model along with the maximum current draw for the load. Consider this example of a Metra F40PHR with the full light package:

- Front Headlight - 20ma

- Front Gyralite - 20ma

- Front Top Red Marker Light - 20ma

- Rear Headlight - 20ma

- Right Ditch Light - 20ma

- Left Ditch Light - 20ma

- Cab Interior Light - 20ma

- Number Board Lights (x2) - 20-40ma depending on the circuit

- Front Red Marker Lights (x2) - 20-40ma depending on the circuit

- Right Strobe Light - 20ma

- Left Strobe Light - 20ma

- Ground Lights (x4) - 20-80ma depending on the circuit

- Summary - 17 LEDs on 12 Total Function Outputs with load of 240ma to 340ma depending on the circuit

That's a lot of lights and a pretty big load. Now in practice not every light will be on at the same time so you probably don't truly need 340ma but they could be...

"Is this really necessary?", you ask. If you are planning an install and will only use the front and rear headlight and you know they are LEDs... probably not. If you are doing an O Scale FT-A with about thirty Incandescent Bulbs for ground lights, interior lights, number board lights, classification lights, headlights... let me tell you a lesson from the school of hard knocks, yeah... you better. Failure to understand the maximum current draw can damage the decoder, the load (LED or bulb), or both. Ouch...

You really have to ask, "How much fun was it installing and troubleshooting seventeen LEDs in that model?

Options include...

- NORMAL OUTPUT FUNCTIONS

- LOGIC-LEVEL FUNCTIONS

- SERVO OUTPUT FUNCTIONS

- FUNCTION INPUTS

NORMAL OUTPUT FUNCTIONS are common, rectified DC output circuits for use in controlling discrete electronic components like LEDs and Incandescent Bulbs. The output voltage is the equivalent of track voltage less voltage drop in the circuit. As an example to establish some sense of relativity, the function output on a decoder is about 12V DC when powered by a command station having a 13.2V nominal track output.

PRO TIP... function outputs are commonly used to power LEDs. Most LEDs used in model railroading are rated at 3.2fV. You must confirm the supply voltage to the function output and add an external resistor to reduce the voltage except in specific cases where the decoder has on-board resistors or circuitry to manage output voltage. Connecting a 12V power supply to a 3.2fV LED will destroy it instantly. There are many variables that affect the actual voltage at the function output. Most professionals and modelers have accepted that a 1k to 2.2k Ohm resistor is sufficient to protect a common LED in most model railroad applications.

PRO TIP... I quit trying to work with incandescent bulbs years ago because they are just not worth the effort. LEDs are cheap and easy enough to install and the will last forever. That said, there are circumstances where it is not practical to covert a model to LED lighting. I use the TCS 1302 DCC Decoder VR1.5 Voltage Regulator - Hardwire exclusively instead of resistors in these cases to manage the power supplied to the bulbs. The device is reasonably inexpensive and so much easier and more reliable than using a resistor.

LOGIC-LEVEL FUNCTIONS are low voltage function outputs used to provide a control signal to a sub-board controller or external device. Logic level functions can be easily converted to normal output functions by adding the necessary hardware such as the SBS4DCC Aux 3-4 Logic Level Function Amplifier Board to the circuit.

SERVO OUTPUT FUNCTIONS are typically 5V outputs with standard 3-pin connection (power, ground, signal) for use with external servos.

FUNCTION INPUTS are special decoder functions that convert input voltage to a signal that controls some logic in the decoder. Examples include a simple input that activates a brake feature or a cam assembly that triggers the chuff sound effect of a steam sound decoder.

An additional consideration when planning the function outputs for an install project is FUNCTION MAPPING, or the ability to remap or reassign the FUNCTION OUTPUT to a specific FUNCTION KEY on the throttle that is different from the default assignment by the manufacturer or standard. Remapping is accomplished by changing, or reprogramming, the value of the controlling CONFIGURATION VARIABLE (CV) in the decoder software.

PRO TIP... the ability to customize the function map varies by decoder brand. Some brands follow the NMRA DCC Standard S-9.2.2 DCC Configuration Variables rigidly and do not have the flexibility to adjust the mapping. Other brands are designed to follow the standard but have the flexibility to customize the function map to suit your own needs and preferences. Be sure to investigate this feature before deciding on a brand or model of decoder if it matter to you.

Be sure to check out the About LEDs & DCC Decoder Installations page that provides additional information on the subject and instructions for how to use LEDs with a DCC Decoder successfully.

STAY-ALIVE INTERFACE

In my humble opinion, the single greatest improvement to model railroading since the invention of the first electric-powered model train has been the development of the STAY-ALIVE DEVICE. Not everyone can produce hand-laid MMR-quality track work. Sometimes things get dirty and things are just not perfect. The dirt and imperfections interfere with electrical conductivity and make our trains run poorly. I hate trains that run poorly. Period.

A simple, low capacitance electrolytic capacitor is considered a stay-alive device. The best stay-alive device is simple circuit consisting of special, high-capacity "super capacitors" and other components and circuitry to control the charge and discharge speeds of the capacitors. The stay-alive device is basically a battery backup for a DCC decoder that supplies power to the on-board processor when the normal power supply circuit is interrupted. A stay-alive device is a relatively inexpensive solution that helps trains run smoothly. Period.

"Which one is best and how much capacitance do I need?", you ask... Anything more than zero is good, the most you can fit is best...

Bottom line, Streamlined Backshop Installations will not do an installation without a stay-alive device. It just makes such a big difference in performance.

Specifications for stay-alive Interface typically include...

- STAY-ALIVE INTERFACE

- KA INPUT VOLTAGE (MAX)

- KA TOTAL CAPACITANCE

STAY-ALIVE INTERFACE is more or less identical to DECODER INTERFACE. The nomenclature is the same but there are generally fewer options available.

KA INPUT VOLTAGE (MAX) is the maximum voltage that can be safely used.

PRO TIP... add a resistor to the +V common connection of the stay-alive device when using the product with high power output DCC controllers typically used for large small-scale layouts or O and G scale layouts.

KA TOTAL CAPACITANCE is the amount of energy the device can store at full charge. Some of this information is estimated because the values are not published but the estimates provide some sense of relative capacitance from one product to another.

PRO TIP... programming issues without inclusion of inrush current protection circuit (resistor diode pair).

PRO TIP... be sure to look for decoders and adapter boards having an on-board stay-alive device to simplify installation.

Be sure to check out the About Stay-Alive Devices & DCC Decoder Installations page for more information on this revolutionary product.

ABOUT DCC SOUND DECODERS

Many sound decoder types

- Motor + Sound

- Motor + Sound + Function

- Motor + Sound + Function + Adapter Board

- Motor + Sound + Function + Adapter Board + Keep Alive Device

- Motor + Sound + Function + Keep Alive Device

- Sound + Function

- Sound Only

Generally you by sound decoder or non-sound decoder, you typically don't "add" sound to non-sound decoder.

Preprogrammed vs programmable.

Sound projects are a compilation of sound files that are assigned to sound memory "slots" in a decoder. The SOUND SLOTS are also usually controlled by FUNCTION KEYS on a DCC Throttle.

SPEAKER INTERFACE: On interface connector

SOUND CHANNELS: 12

SOUND PROCESSOR: 32-bit

SAMPLE RATE: 31.25 kHz

SOUND MEMORY: 128 Mbit

AMP POWER (MAX): 1.5W

AMP IMPEDANCE: 4-32 Ohms

Regarding speakers...

link to impedance calculator

PRO TIP... The easiest way to fatally damage a DCC Sound Decoder is to short the speaker or exceed the impedance rating.

Be sure to check out the About Speakers & DCC Decoder Installations page that provides additional information on the subject and instructions for how to install a DCC Sound Decoder successfully.

CV PROGRAMMING: Service Mode + P.O.M.

FIRMWARE UPDATE: Yes - LokProgrammer required

SOUND FILE UPDATE: Yes - LokProgrammer required

PROTOCOL: NMRA DCC

BI-DIRECTIONAL COMMUNICATION: RailCom Plus

Regarding sound decoders...

Two types of memory RAM and ROM, CVs vs Sound Files

Reloadable vs fixed

larger size and always requires a speaker

ADDITIONAL FEATURES: Speaker NOT INCLUDED

NOTES (1): * - Optional configuration - see manual

NOTES (2): ** - Optional 2 or 3 wire KA interface

what else?